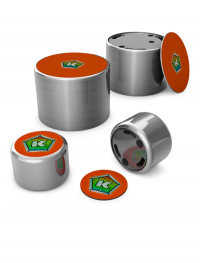

Locking cylinder

for service and gate valves

KEEPER-Locking-Cylinder, made by KETTLER, prevents unauthorised or accidental opening or shutting of valves in the gas- and water-supply sector.

KEEPER-Locking-Cylinder is constructed and designed to hinder external mechanical manipulation significantly. KEEPER is assembled by simply mounting it on top of the spindle extension's operating element with the special tool provided. When assembled, the locking cylinder is spinning freely and is fitted with a protective red cover. Depending on the situational requirements a variety of models are available for KEEPER-Locking-Cylinder.

PROTECTION CLASS I – LONG TERM

Prevention of unauthorised or accidental access

for gate valves – KEEPER POM

- right locking, for shut valves

- left locking, for open valves

for service valves – KEEPER POM

- right locking, for shut valves

- left locking, for open valves

PROTECTION CLASS II – SHORT TERM

Prevention of sabotage or unauthorised access

for gate valves – KEEPER structural steel/42CrMo4

- right locking, for shut valves

- left locking, for open valves

for service valves – KEEPER structural steel/42CrMo4

- right locking, for shut valves

- left locking, for open valves

Material: PE = Polyethyle | PE-HD = Polyethylen high density | PE-LD = Polyethylen low density | PE-LLD = Polyethylen linear low density | PP = Polypropylen | PA = Polyamid | PA-GF = Polyamid glass fibre reinforced | POM = Polyoxymethylene | EPDM = Ethylene propylene diene monomer rubber | Structural steel ST37-2 = S235JR = DIN EN 10025 | Malleable cast iron = DIN EN 1562 | Stainless steel V2A = Cr/Ni-Steel = 1.4301 | tZn = hot dip galvanised | gZn = electrolytically galvanised | 11SMnPb37 = DIN EN 10087 | 42CrMo4 = Q&T Steel quenched and tempered = DIN EN 10083 | Niro = non corroding steel