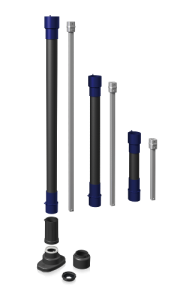

KIT-Coupling-Module

is used to increase cover depth of KIT-Standard-Telescopes as well as KIT-Multi-Telescopes. KIT-Coupling-Modules can be assembled in just a few steps by convenient plug on mechanics. By using one or more modules, any desired cover depth can be met. The entire KIT-System can be disassembled into its basic modules using the dismantling tool provided. All coupling modules are designed to be fitted with all available service and gate valve coupling sockets of the KIT product range. By having a number of different coupling module sizes in stock, the variety of different telescopes can be reduced significantly while inventory turnover ratio is maximised

is used to increase cover depth of KIT-Standard-Telescopes as well as KIT-Multi-Telescopes. KIT-Coupling-Modules can be assembled in just a few steps by convenient plug on mechanics. By using one or more modules, any desired cover depth can be met. The entire KIT-System can be disassembled into its basic modules using the dismantling tool provided. All coupling modules are designed to be fitted with all available service and gate valve coupling sockets of the KIT product range. By having a number of different coupling module sizes in stock, the variety of different telescopes can be reduced significantly while inventory turnover ratio is maximised

KIT-Dismantling-Tool

KIT-Dismantling-Tools allow for quick and easy disassembly of the entire KIT-System into its basic modules.

By using a variety of dirt disks and adaptors an ideal fit to most valve designs can be ensured.

KIT-Coupling-Module build-up

- Protective cover

PE-HD - Upper coupling tube

PE-HD - Coupling socket

Malleable cast iron gZn - Square pipe

Structural steel tZn or stainless steel - Tubing

PE-HD - Lower coupling tube

PE-HD - Compression piece

Hull = PA, Spring/bolt: Niro

Material: PE = Polyethyle | PE-HD = Polyethylen high density | PE-LD = Polyethylen low density | PE-LLD = Polyethylen linear low density | PP = Polypropylen | PA = Polyamid | PA-GF = Polyamid glass fibre reinforced | POM = Polyoxymethylene | EPDM = Ethylene propylene diene monomer rubber | Structural steel ST37-2 = S235JR = DIN EN 10025 | Malleable cast iron = DIN EN 1562 | Stainless steel V2A = Cr/Ni-Steel = 1.4301 | tZn = hot dip galvanised | gZn = electrolytically galvanised | 11SMnPb37 = DIN EN 10087 | 42CrMo4 = Q&T Steel quenched and tempered = DIN EN 10083 | Niro = non corroding steel