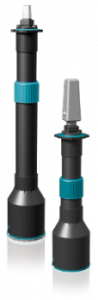

ECO-Extension

By using ECO-Extension, ECO-Telescopes for service as well as gate valves, may be elongated retroactively after assembly of the extension spindle and completion of backfilling. ECO-Extension is conveniently mounted to the top of the telescope by simple plug on an locking mechanics tool and bolt free. By reducing or extending the height of the existing telescope below, cover depth can be adjusted to the optimum without complications. Adaptors at the bottom end of the ECO-Extension bell tube are made of glass fibre reinforced polyamid (PA-GF) and are designed to match the centring cap of the ECO-Telescope, ensuring maximum stability.

By using ECO-Extension, ECO-Telescopes for service as well as gate valves, may be elongated retroactively after assembly of the extension spindle and completion of backfilling. ECO-Extension is conveniently mounted to the top of the telescope by simple plug on an locking mechanics tool and bolt free. By reducing or extending the height of the existing telescope below, cover depth can be adjusted to the optimum without complications. Adaptors at the bottom end of the ECO-Extension bell tube are made of glass fibre reinforced polyamid (PA-GF) and are designed to match the centring cap of the ECO-Telescope, ensuring maximum stability.

![]()

![]()

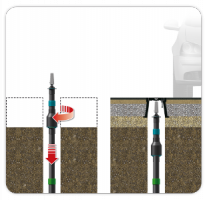

ECO-Extensions are downwardly compatible

By use of an adaptor ring KETTLER-Telescopes for service as well as gate valves of earlier generations are upgradable with new ECO-Extensions. For assembly the adaptor ring is simply plugged between the existing telescope and the extension without the use of any tools.

For assembly the adaptor ring is simply plugged between the existing telescope and the extension without the use of any tools.

ECO-MEMO-Extension for service and gate valves

By using MEMO-Extensions ECO-Telescopes can be fitted with a MEMO indicator retroactively. Mechanics integrated into the head of the ECO-MEMO-Extension indicate the open or shut position of the valve below by colour. The MEMO display can be configured by shutting and opening the valve once and is then secured against manipulation. MEMO function is available for valves with a minimum of 5 and a maximum of 56 rotations.

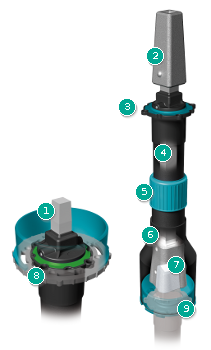

ECO-Extension build-up

- Operating element for service valves

Structural steel tZn or stainless steel - Operating element for gate valves

Structural steel tZn - Centring cap

PE-HD - Square rod

Structural steel tZn or stainless steel - Sealing ring

PE-LD - Tubing and bell tube

PE-HD - Coupling socket for service or gate valves

Malleable cast iron gZn - Adaptor ring for small centring cap

PA-GF - Adaptor ring for large centring cap

PA-GF

Material: PE = Polyethyle | PE-HD = Polyethylen high density | PE-LD = Polyethylen low density | PE-LLD = Polyethylen linear low density | PP = Polypropylen | PA = Polyamid | PA-GF = Polyamid glass fibre reinforced | POM = Polyoxymethylene | EPDM = Ethylene propylene diene monomer rubber | Structural steel ST37-2 = S235JR = DIN EN 10025 | Malleable cast iron = DIN EN 1562 | Stainless steel V2A = Cr/Ni-Steel = 1.4301 | tZn = hot dip galvanised | gZn = electrolytically galvanised | 11SMnPb37 = DIN EN 10087 | 42CrMo4 = Q&T Steel quenched and tempered = DIN EN 10083 | Niro = non corroding steel